Oyster Opener

Project Overview

For ME 318: Computer Aided Product Realization, I designed, 3D modeled, and CNC machined a bottle opener inspired by an oyster and pearls. The project required creating a bottle opener based on the theme “juxtaposition.” This design juxtaposes material and texture while prioritizing elegance and comfort.

Processes/Tools

3D Printing, CNC Milling, CAD and CAM on Autodesk Fusion 360, 2D and 3D CAM toolpaths, Soft Jaws

Material

Aluminum stock, Pearl beads

Design Process

Ideation, 2 rounds of prototyping, CAD, CAM, and machining

Ideation

I used techniques such as mindmapping, lists, and sketching in order to come up with the oyster and pearl design direction.

Rapid Prototyping

I initially prototyped with cardboard to test the ergonomics of my design, specifically looking at the angle of the top section and the overall size and shape. I also used beads to test how I would incorporate pearls into the design.

CAD, CAM, and More Prototyping

Testing out different positions for the pearls

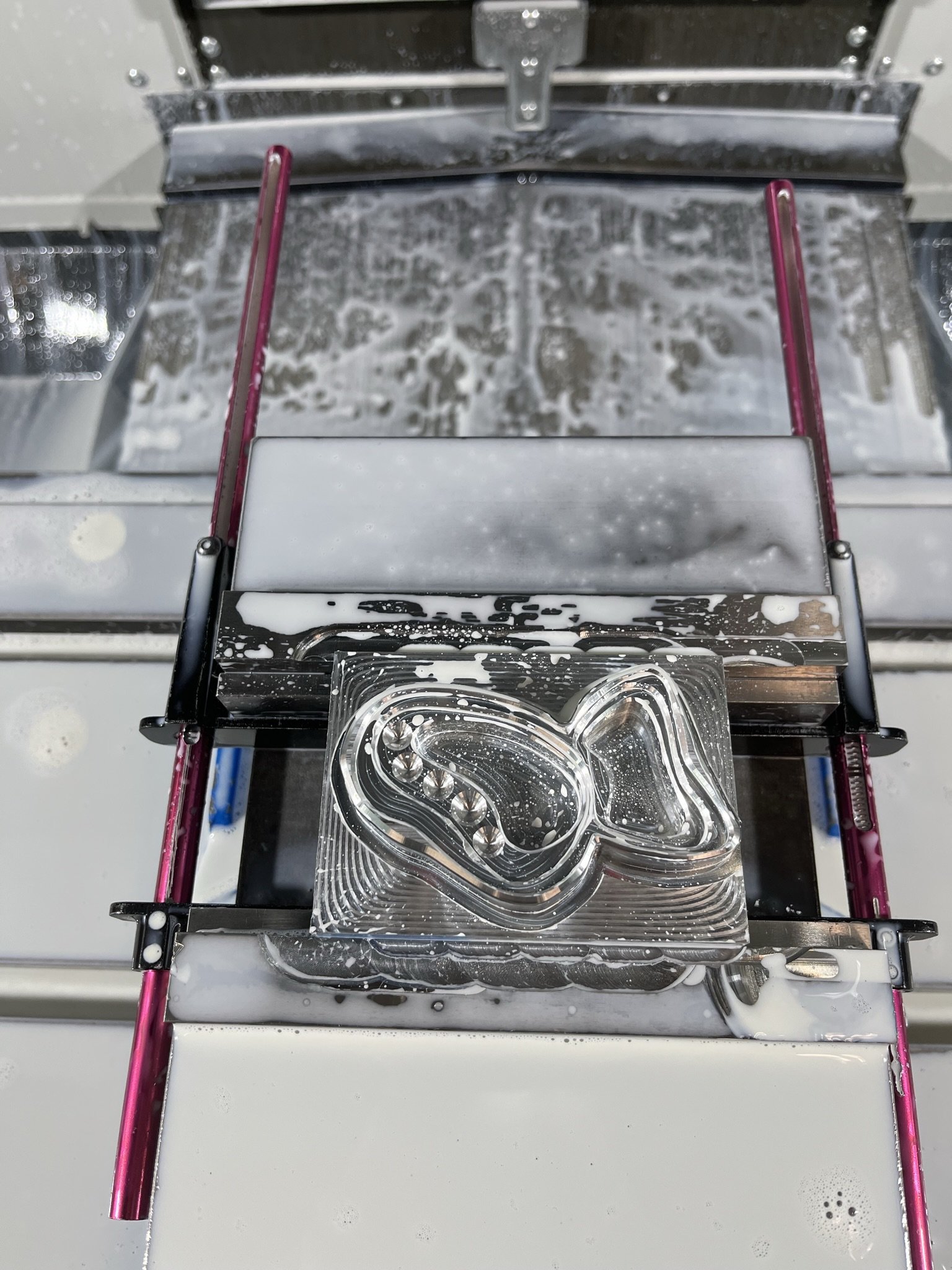

Setting up CAM toolpaths (pocket, adaptive, 2D chamfer, scallop, and debur) and ensuring that my design has a clean machine finish.

Final CAD prototype

Back to CAD! I decided to increase the radius of internal corners in my design in order to use less tooling

3D printing the final design to ensure functionality

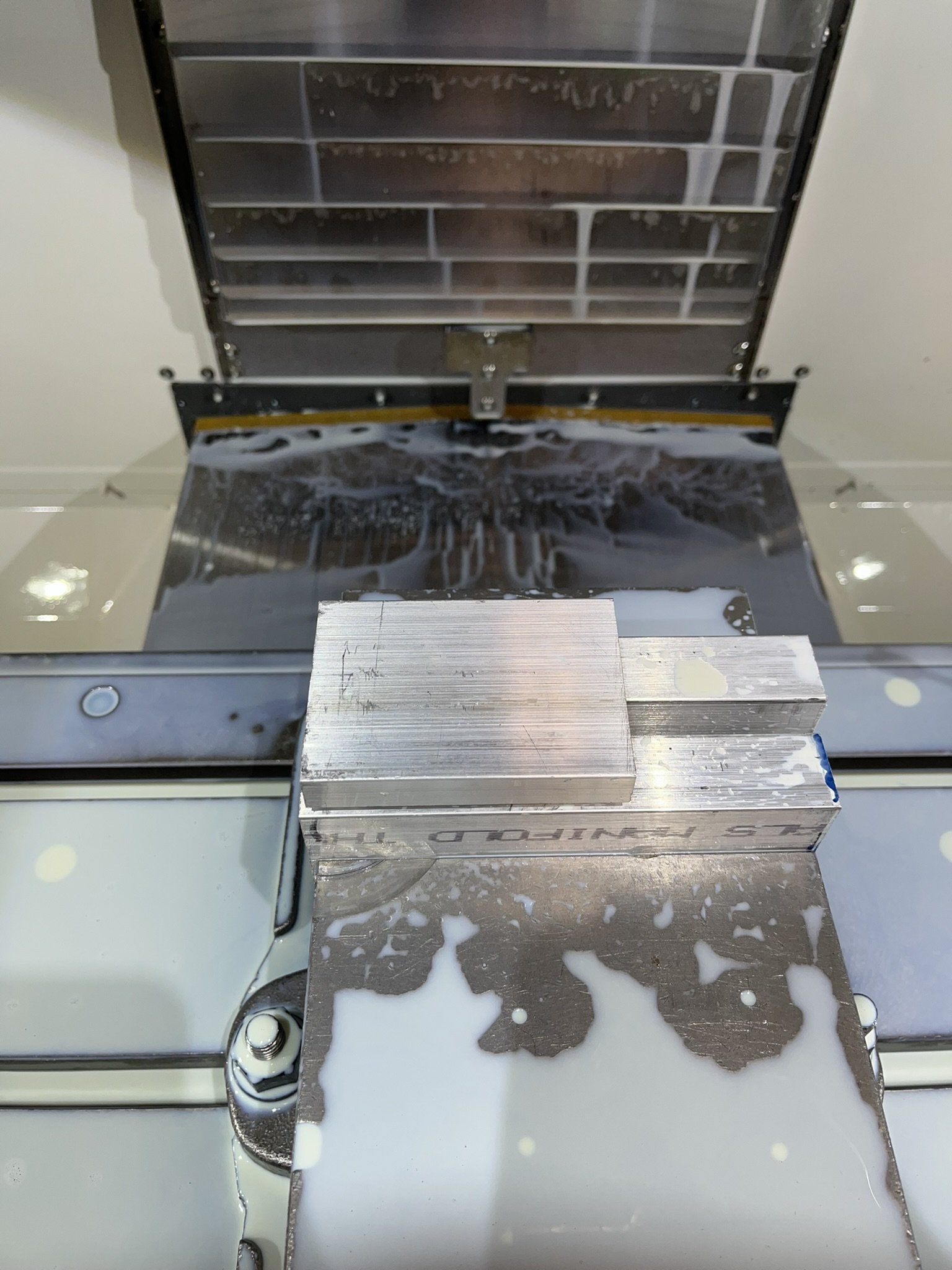

CAD/CAM for the soft jaws

Machining

1. Cut top side (50 minute cut)

2. Cut soft jaws that will clamp the part as it cuts the second side.

3. Cut bottom side (1 hour cut)